At a Glance:

-Key Benefits of COB LED

-Key Benefits of GOB LED

-What the difference between HOB, GOB, COB and SMD?

-Can both COB and GOB be used in rental projects?

Introduction

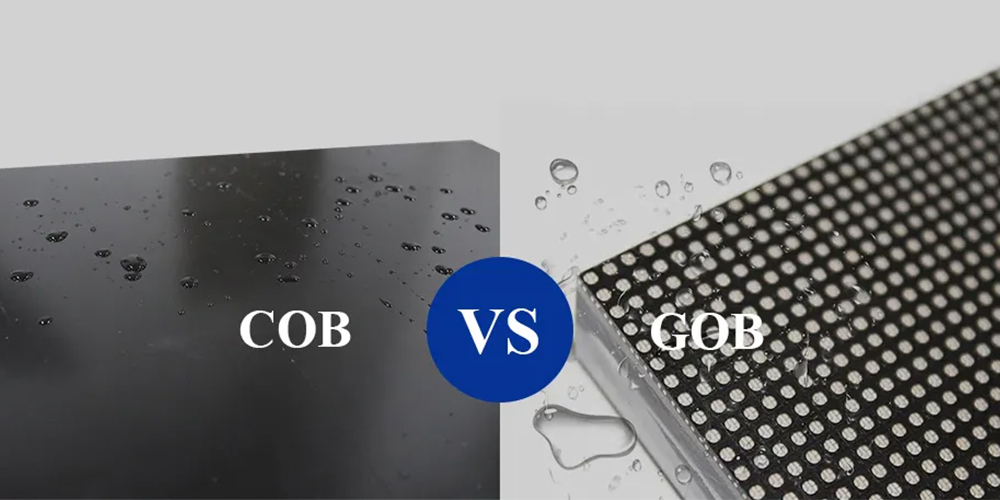

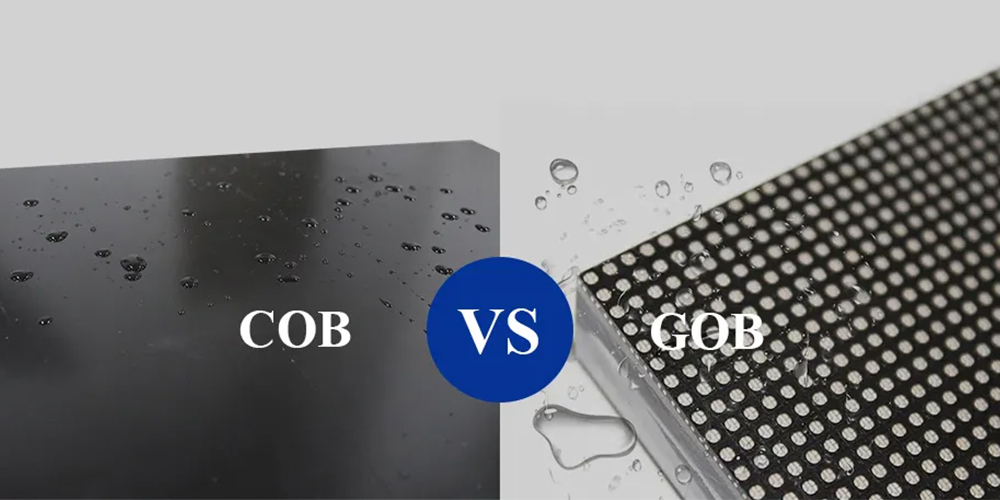

The LED display industry has developed rapidly, and two packaging technologies—COB (Chip on Board) and GOB (Glue on Board)—have become hot topics. Both aim to improve durability, visual quality, and reliability, but they achieve this in different ways. This article will break down the core differences, advantages, and considerations for COB LED display and GOB LED displays, helping integrators, rental companies, and end users choose the right solution.

What Is COB LED Technology?

COB (Chip on Board) refers to directly mounting multiple LED chips onto a substrate. Instead of packaging each diode individually, COB integrates them as a unified module.

Key Benefits of COB:

- Seamless Viewing: Because of its tight pixel structure, COB provides excellent uniformity and smooth visuals.

- Durability: With no traditional lamp beads exposed, COB is resistant to physical impact and static electricity.

- High Reliability: COB modules are dust-proof and moisture-resistant, suitable for demanding environments.

This technology is often seen in fine-pitch LED video walls, especially in control rooms, broadcasting studios, and corporate boardrooms where image accuracy and stability are critical.

What Is GOB LED Technology?

GOB (Glue on Board) uses a transparent protective resin coating applied to the surface of traditional SMD LEDs. Instead of altering the chip packaging method itself, it enhances existing displays with an extra protective layer.

Key Benefits of GOB:

- Extra Protection: The hardened resin makes the surface resistant to moisture, dust, and collisions.

- Cost-Effective: Since it builds on conventional SMD LED packaging, GOB often provides a balance between performance and affordability.

- Flexible Applications: GOB can be applied to rental LED Panels, outdoor displays, or environments with heavy foot traffic where accidental impact is common.

Essentially, GOB is like giving a shield to SMD LEDs, making them tougher without completely changing their structure.

COB vs GOB: Head-to-Head Comparison

Feature

|

COB LED

|

GOB LED

|

Technology

|

Direct chip-on-substrate integration

|

Transparent resin coating on SMD LEDs

|

Durability

|

High—chips embedded and sealed

|

Strong—extra protective layer

|

Visual Quality

|

Excellent uniformity, ultra-fine pixel

|

Very good, depends on underlying SMD tech

|

Cost

|

Higher due to advanced packaging process

|

More affordable, cost-effective upgrade

|

Applications

|

High-end indoor fine-pitch installations

|

Rental, retail, outdoor, high-traffic use

|

Which Technology Should You Choose?

- Choose COB if your project demands the highest level of image precision, seamless fine pitch, and reliability in mission-critical environments.

- Choose GOB if you need a versatile, durable, and cost-efficient solution that can withstand physical wear while maintaining solid performance.

Both have their place in the LED ecosystem: COB leads in premium indoor installations, while GOB excels in flexible, impact-prone applications.

Conclusion

COB and GOB are not rivals, but complementary packaging technologies. COB pushes the limits of fine-pitch performance with strong durability, while GOB extends the lifespan of traditional LEDs by adding robust surface protection.

For B2B buyers, integrators, or rental service providers, the right choice depends on budget, environment, and performance requirements. With the continuous evolution of LED packaging, both COB and GOB are shaping the future of reliable, durable, and visually stunning led screen display.

Market Applications & Future Trends

Where COB Shines

COB is widely adopted in video gear command centers, control rooms, and corporate meeting spaces where precision and reliability are paramount. Its seamless visuals and fine pixel pitches make it ideal for broadcast studios, medical imaging, and government monitoring systems. As pixel pitches continue to shrink, COB is positioned to lead the next generation of ultra-high-definition retail led display cases.

Where GOB Leads

GOB technology thrives in rental, staging, and high-traffic retail spaces. Its protective resin layer ensures panels withstand frequent transport, setup, and tear-down, while still maintaining high image quality. GOB is also gaining traction in outdoor advertising, thanks to its durability against dust, moisture, accidental damage and without white spot on displays.

Looking Ahead

The future of LED packaging is likely to blend the strengths of both technologies. Manufacturers are already experimenting with hybrid models that combine COB’s integration with GOB’s protective coating, offering a balance of durability, cost-efficiency, and fine-pitch visuals. For B2B buyers, staying informed about these trends ensures they invest in technology that not only meets today’s needs but also adapts to tomorrow’s demands.

Frequently Asked Questions

Which Technology Should You Choose?

- Choose COB if your project demands the highest level of image precision, seamless fine pitch, and reliability in mission-critical environments.

- Choose GOB if you need a versatile, durable, and cost-efficient solution that can withstand physical wear while maintaining solid performance.

Both have their place in the LED ecosystem: COB leads in premium indoor installations, while GOB excels in flexible, impact-prone applications.

Conclusion

COB and GOB are not rivals, but complementary packaging technologies. COB pushes the limits of fine-pitch performance with strong durability, while GOB extends the lifespan of traditional LEDs by adding robust surface protection.

For B2B buyers, integrators, or rental service providers, the right choice depends on budget, environment, and performance requirements. With the continuous evolution of LED packaging, both COB and GOB are shaping the future of reliable, durable, and visually stunning led screen display.

Market Applications & Future Trends

Where COB Shines

COB is widely adopted in video gear command centers, control rooms, and corporate meeting spaces where precision and reliability are paramount. Its seamless visuals and fine pixel pitches make it ideal for broadcast studios, medical imaging, and government monitoring systems. As pixel pitches continue to shrink, COB is positioned to lead the next generation of ultra-high-definition retail led display cases.

Where GOB Leads

GOB technology thrives in rental, staging, and high-traffic retail spaces. Its protective resin layer ensures panels withstand frequent transport, setup, and tear-down, while still maintaining high image quality. GOB is also gaining traction in outdoor advertising, thanks to its durability against dust, moisture, accidental damage and without white spot on displays.

Looking Ahead

The future of LED packaging is likely to blend the strengths of both technologies. Manufacturers are already experimenting with hybrid models that combine COB’s integration with GOB’s protective coating, offering a balance of durability, cost-efficiency, and fine-pitch visuals. For B2B buyers, staying informed about these trends ensures they invest in technology that not only meets today’s needs but also adapts to tomorrow’s demands.

Frequently Asked Questions

1. What is the difference between SMD, GOB and COB?

SMD LED: Standard — each LED is exposed on the board, bright but fragile.

GOB LED: Protective coat — like wrapping SMD with transparent glue, making it anti-collision, waterproof, dustproof.

COB LED: Chip-on-board — LEDs are directly sealed on the board, no lamp beads sticking out, ultra-thin, seamless, super durable.

2. Is COB always more expensive than GOB?

Generally yes, because COB involves a more advanced manufacturing process. GOB tends to be more budget-friendly while still offering solid protection.

3. Can both COB and GOB be used in rental projects?

Yes. GOB is especially popular in rental and touring events due to its resistance to collisions, while COB is chosen for high-end rental applications where ultra-fine pitch and superior image quality are required.

4. How do COB and GOB affect maintenance?

Both reduce maintenance needs compared to traditional SMD displays. COB reduces issues like dead pixels and dust damage, while GOB minimizes surface wear and accidental breakage.

5. What the difference between HOB and GOB?

HOB LED: Hardened-on-board — a more advanced encapsulation, stronger hardness and impact resistance, great for fine-pitch.

GOB LED: Glue-on-board — softer coating protection, mainly for rental and outdoor use.

Think of it like this:

SMD = bare candy

GOB = candy with a soft wrapper

COB = chocolate bar, sealed and solid

HOB = hard candy, tougher shell